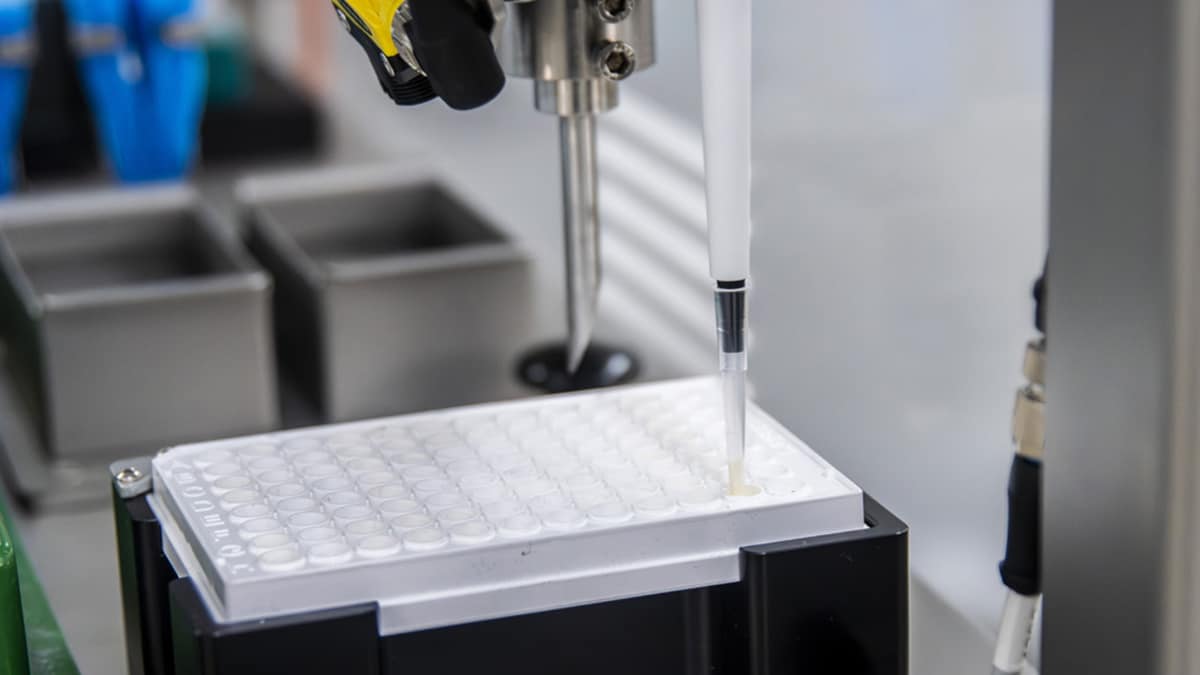

Aliquoting & puncturing robot

The Aliquoting & Puncturing Robot automates and standardizes the preparation of milk carton samples, speeding up the workflow and ensuring consistent, reliable, and efficient quality control of finished products

Aliquoting & puncturing robot – Automation of milk brick sample preparation

Technical Specifications of the Aliquoting and Puncturing Robot*

| Throughput / Capacity | 5 crates of samples, fills microwell plate in ~50min |

| Power Supply | 220 – 240 VAC ±10%, 50 – 60 Hz, 10 A |

| Dimensions | 1800W × 1000D × 1980H mm (can be customised to suit individual needs) |

| Standards | AS/NZS 4024:2014, IEC 60204-1:2016, ISO 13849-1:2015, Regulation 2023/1230/EU – Machinery |

*Specifications subject to change without any prior notice.

Functions of the Aliquoting and Puncturing Robot

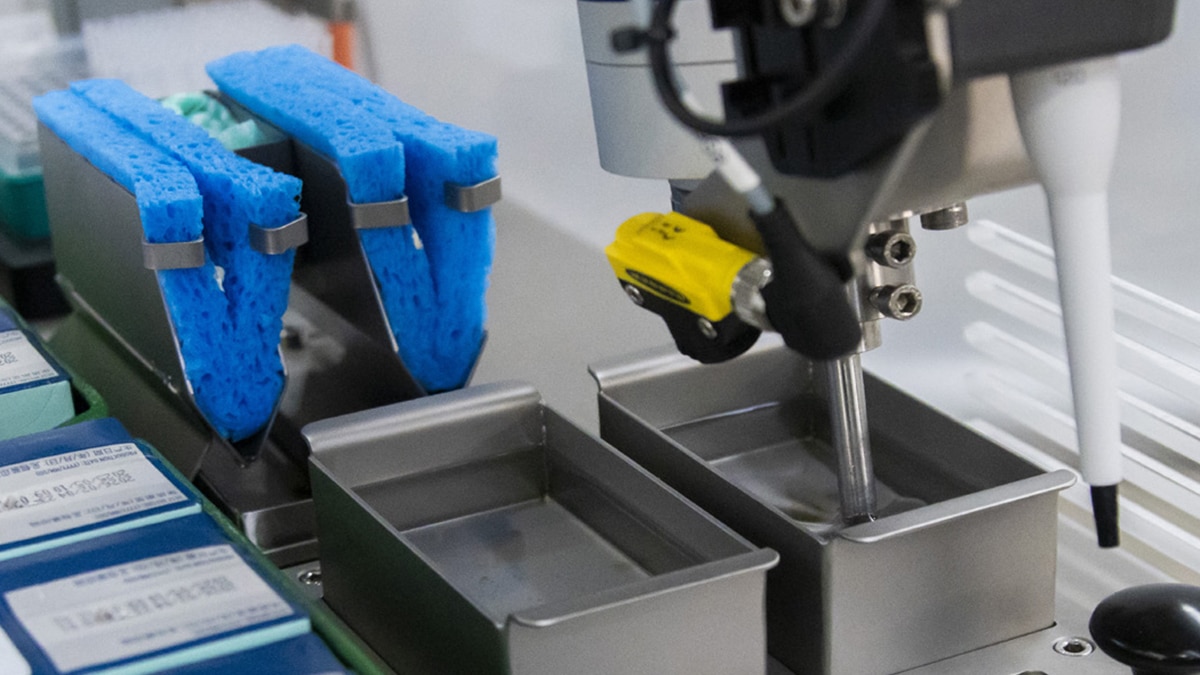

The Aliquoting and Puncturing Robot automates carton puncturing and precise, repeatable aliquoting, completing a full microwell plate in about 50 minutes. It supports two common carton sizes (1 L and 200 mL), auto-loads and ejects pipette tips, and self-cleans with an ethanol wipe-and-wash between samples to prevent cross-contamination.

Key Benefits of the Aliquoting and Puncturing Robot

- Faster, sterile sample preparation – automates carton puncturing & aliquoting and self-cleans with ethanol between samples to avoid cross-contamination.

- Consistent and traceable results – delivers precise, repeatable aliquots with optional Vision/OCR and Insights integration for end-to-end traceability and live KPIs.

- Higher throughput – fills a microwell plate in ~50 minutes and runs up to five crates per cycle.

- Reduced manual effort – removes manual puncturing; auto-loads/ejects pipette tips and features auto-recovery to minimise downtime.

- Improved lab safety & ergonomics – frees technicians from repetitive tasks and helps lower repetitive strain injuries.

- Flexible, future-proof setup – supports 1 L and 200 mL cartons, offers modes for other container types, and can integrate with various robot brands.

Technical Specifications of the Aliquoting and Puncturing Robot*

| Throughput / Capacity | 5 crates of samples, fills microwell plate in ~50min |

| Power Supply | 220 – 240 VAC ±10%, 50 – 60 Hz, 10 A |

| Dimensions | 1800W × 1000D × 1980H mm (can be customised to suit individual needs) |

| Standards | AS/NZS 4024:2014, IEC 60204-1:2016, ISO 13849-1:2015, Regulation 2023/1230/EU – Machinery |

*Specifications subject to change without any prior notice.

MAINTENANCE & SUPPORT

Customer service has always been a priority for Bentley Instruments. We guarantee our customers prompt assistance for optimum productivity.

In order to guarantee the highest level of productivity, our team of technicians takes care of installation, training and diagnostics remotely and locally.

The FreshDesk platform is available by registering and gives you access to our e-service platform: e-ticket service to ask our engineers about your problems, technical databases (equipment history, technical notes, manuals...), diagnostic tools (problem/solution), worldwide network of production engineers and after-sales service for a quick and interactive assistance at your disposal at any time.

Fill out this form and download the product brochure in PDF format

BENTLEY INSTRUMENTS EU

ZA Brunehaut 840 rue Curie

62161 Maroeuil - France

+33 (0)2 85 52 90 73

Fax : +33 (0)3 20 09 87 12

info@bentleyinstruments.eu

BENTLEY INSTRUMENTS INC.

4004 Peavey Rd Chaska

Minnesota 55318 - USA

+1 952 448 7600

+1 952 368 3355

info@bentleyinstruments.com